Nominal diameter: DN25 ~ 300mm

Nominal pressure: PN1.6 ~ 4.0MPa

Main material: WCB, 304,316

Connection: Wafer, flange

Flange Standard: GB, ANSI, DIN, JIS

Electric actuator: switching, regulation, explosion proof

Design and manufacture: GB / T12237 / 1989, ASME B16.34, API608

Length of the structure: GB / T12221, ASME B16.10

Connection dimensions: GB 9113.1, ASME B16.5

Test standard: GB / T13927-1992, API 598, API6D

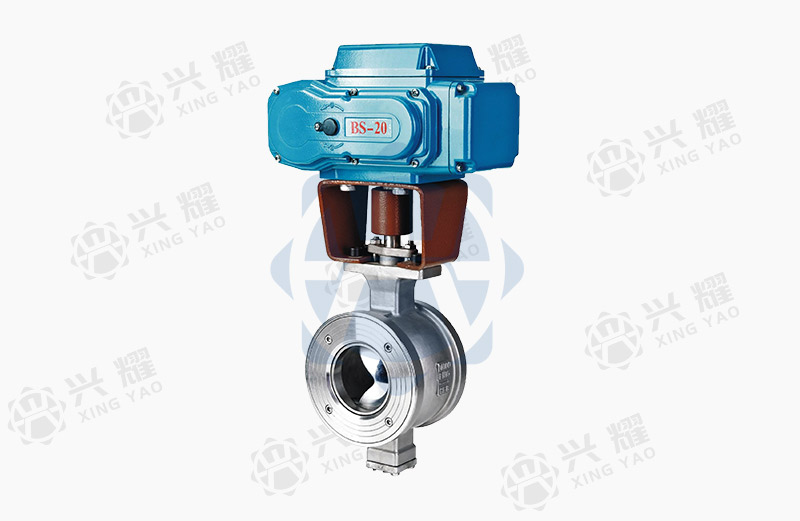

【VQ947H / VQ977H electric V-type ball valve - Product Description】

Electric

V-ball valve with a cylindrical spring preloaded compensated movable

metal seat structure, sealing performance and reliable. Core and valve

seat will not produce jamming or detachment, long service life. The

V-shaped cutout on the core has a shear effect with the metal seat,

especially suitable for controlling medium with high viscosity, fiber,

solid particles and slurry. Paper pulp industry structure is

particularly superior. Valve flow capacity, pressure loss is small, and

the medium will not be deposited in the valve body cavity, the valve not

only has a similar ratio of flow characteristics, adjustable range, the

maximum adjustable ratio of 100: 1, but also with accurate Adjustment

and reliable positioning of the function.

[VQ947H / VQ977H electric V-type ball valve - the main parts material]

|

Part Name |

Material |

|

|

Body, bonnet |

WCB |

CF 8 |

|

Sealing ring |

2Cr13 + Nitriding |

304 + nitriding |

|

Sphere |

2Cr13 + hard grid |

304 + hard grid |

|

Seat, stem |

2Cr13 |

304 |

|

Gasket |

Flexible graphite + stainless steel |

Flexible graphite + stainless steel |

|

Studs |

35CrMoA |

1Cr18Ni9Ti |

[VQ947H / VQ977H electric V-type ball valve - the main performance specifications]

|

Nominal pressure |

Test pressure (MPa) |

Suitable media |

proper temperature |

|

|

Shell test |

Seal test |

|||

|

1.6 |

2.4 |

1.76 |

Water, oil, gas and high viscosity, |

-28 ℃ ~ ≤550 ℃ |

|

2.5 |

3.75 |

2.75 |

||

|

4.0 |

6.0 |

4.4 |

||

[VQ947H / VQ977H electric V-type ball valve - the main dimensions]

|

PN |

Nominal diameter |

Size (mm) |

||||||||

|

(Mm) |

(In) |

W |

L |

W1 |

L1 |

d |

d1 |

H1 |

H |

|

|

PN1.6MPa |

25 |

- |

50 |

- |

25 |

- |

64 |

38 |

57 |

200 |

|

40 |

- |

60 |

- |

25 |

- |

82 |

49 |

63 |

205 |

|

|

50 |

- |

75 |

124 |

32 |

62 |

100 |

60 |

92 |

225 |

|

|

65 |

- |

80 |

145 |

38 |

72.5 |

120 |

75 |

100 |

235 |

|

|

80 |

- |

100 |

165 |

45 |

82.5 |

131 |

89 |

108 |

260 |

|

|

100 |

- |

115 |

194 |

50 |

97 |

158 |

113 |

117 |

270 |

|

|

125 |

- |

135 |

210 |

55 |

105 |

180 |

140 |

140 |

320 |

|

|

150 |

- |

160 |

229 |

65 |

114.5 |

216 |

164 |

177 |

340 |

|

|

200 |

- |

200 |

243 |

80 |

121.5 |

268 |

205 |

200 |

390 |

|

|

250 |

- |

240 |

297 |

90 |

148.5 |

326 |

259 |

252 |

420 |

|

|

300 |

- |

- |

338 |

- |

169 |

- |

300 |

270 |

510 |

|

|

PN2.5MPa |

25 |

- |

50 |

- |

25 |

- |

64 |

38 |

57 |

200 |

|

40 |

- |

60 |

- |

25 |

- |

82 |

49 |

63 |

205 |

|

|

50 |

- |

75 |

124 |

32 |

62 |

100 |

60 |

92 |

225 |

|

|

65 |

- |

85 |

145 |

38 |

72.5 |

120 |

75 |

100 |

235 |

|

|

80 |

- |

100 |

165 |

45 |

82.5 |

131 |

89 |

108 |

260 |

|

|

100 |

- |

115 |

194 |

50 |

97 |

158 |

113 |

117 |

270 |

|

|

125 |

- |

135 |

210 |

55 |

105 |

180 |

140 |

140 |

320 |

|

|

150 |

- |

160 |

229 |

65 |

114.5 |

216 |

164 |

177 |

340 |

|

|

200 |

- |

200 |

243 |

80 |

121.5 |

268 |

205 |

200 |

390 |

|

|

250 |

- |

240 |

297 |

92 |

148.5 |

326 |

259 |

252 |

420 |

|

|

300 |

- |

- |

338 |

- |

169 |

- |

300 |

270 |

510 |

|

|

ClASS150 |

25 |

- |

50 |

- |

25 |

- |

64 |

38 |

57 |

200 |

|

40 |

11/2 |

65 |

- |

25 |

- |

82 |

49 |

63 |

205 |

|

|

50 |

2 |

75 |

124 |

32 |

62 |

100 |

60 |

92 |

225 |

|

|

65 |

21/2 |

85 |

145 |

38 |

72.5 |

120 |

75 |

100 |

235 |

|

|

80 |

3 |

100 |

165 |

45 |

82.5 |

131 |

89 |

108 |

260 |

|

|

100 |

4 |

115 |

194 |

50 |

97 |

158 |

113 |

117 |

270 |

|

|

125 |

5 |

135 |

210 |

55 |

105 |

180 |

140 |

140 |

320 |

|

|

150 |

6 |

160 |

229 |

65 |

114.5 |

216 |

164 |

177 |

340 |

|

|

200 |

8 |

200 |

243 |

80 |

121.5 |

268 |

205 |

200 |

390 |

|

|

250 |

10 |

240 |

297 |

92 |

148.5 |

326 |

259 |

252 |

420 |

|

|

300 |

12 |

- |

338 |

- |

169 |

- |

||||

Hotline:

Hotline:

+86 13920768658

+86 13920768658