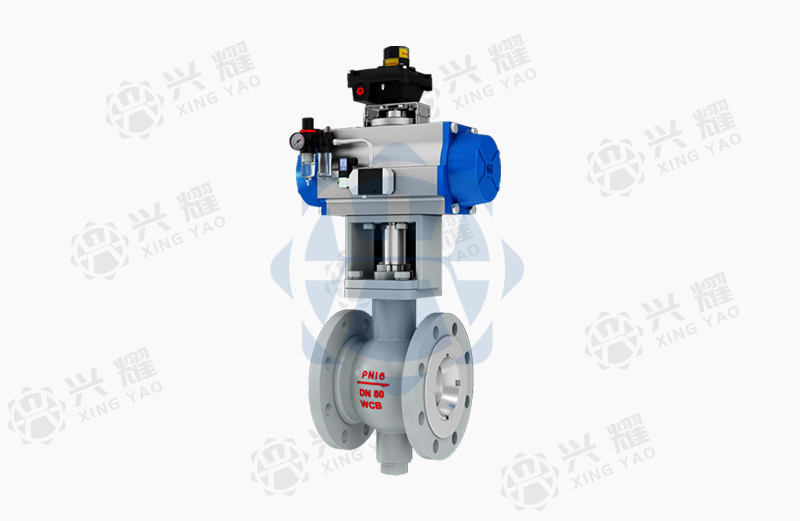

Nominal diameter: Wafer DN25~500mm

Nominal: PN1.6 ~ 2.5MPa

Connection: Wafer / flange

Medium temperature: W1: -40 ~ 180 ℃ W2: -40 ~ 300 ℃ W3: -30 ~ 425 ℃ W4: -40 ~ 425 ℃

Body material: Carbon (C), stainless steel (P4, P6)

Design basis: GB standard

Besign criteria: GB / 12237

Ligation Blue size: GB / 9113, JB / T79

Test and test: JB / T9092

Pneumatic V-type ball valve features

1, compact structure, small size, can be installed vertically and so on.

2, with excellent regulation features: V-type ball valve has an

approximate equal percentage of the inherent flow characteristics and up

to 300: 1 adjustable 1, compact, small size, can be installed

vertically and so on.

2, with excellent regulation features: V-type ball valve has an

approximate equal percentage of the inherent flow characteristics and up

to 300: 1 adjustable ratio. V-valves therefore provide precise control

over a wide range of variations.

3, the maximum flow volume: Due to its streamlined shape and full

right-angle rotary control, so that the maximum volume is particularly

high, particularly large flow capacity, flow resistance is small, so you

can use smaller and more economical and practical valve size.

4, V-type ball valve with double bearing structure, high mechanical

stability, low starting torque to ensure that the valve has excellent

sensitivity and sensing speed.

5, the most reliable (safety): the valve body as a whole, durable, the

operation from the pipeline pressure, and to avoid valve leakage.

6, the superior sealing of the metal seat: V-type ball valve with

movable metal seat, self-compensation function, and has superior sealing

performance and long service life. In the flow direction, the amount of

leakage ≤ 10-6 × rated flow coefficient.

7, super shear capacity: V-type ball valve with a metal seal

structure, V-shaped ball valve seat and the metal valve seat during the

rotation, V-notch and the valve seat to produce a strong shear force to

cut off impurities such as fiber , And has a self-cleaning function to

prevent the valve stuck phenomenon.

| Technical Parameters | |

| Nominal diameter | Clamp DN25 ~ 250mm / flange DN25 ~ 500mm |

| Connection method | Clip / Flange |

| Cylinder configuration | AT series, GT series, AW series, import actuator series |

| Cylinder form | Double acting, single acting (spring return) |

| control method | Two off (switch), adjustable, three-stage (opening degree optional) |

| Nominal pressure | 16,25bar (Please specify when ordering for higher pressure) |

| Air pressure | Double role: 4 ~ 8bar, single role: 5 ~ 8bar |

| Medium temperature | W1: -40 to 180 ° C W2: -40 to 300 ° C W3: -30 to 425 ° C W4: -40 to 425 ° C |

| Ambient temperature | Standard type: -20 ~ 80 ℃ |

| Body material | Carbon steel (C), stainless steel (P4, P6) |

| Sealing material | Polytetrafluoroethylene (F), para-polyphenylene (PPL), metal hard seal (H), cemented carbide (Y) |

Note: Other special sealing materials or special temperature can also be designed and manufactured according to customer requirements

| PN (MPa) | DN (mm) | Size (mm) | ||||||||

| L | The folder connection | Flange connection | H | |||||||

| D | D | D1 | D2 | D6 | b | zd | ||||

| 1.6 | 25 | 102 | 64 | 115 | 85 | 5 | - | 14/16 | 4-14 | 233 |

| 40 | 114 | 82 | 145/150 | 110 | 85/84 | - | 16/18 | 4-18 | 280 | |

| 50 | 124 | 100 | 160/165 | 125 | 100/99 | - | 16/20 | 4-18 | 362 | |

| 65 | 145 | 118 | 180/185 | 145 | 120/188 | - | 18/20 | 4-18 | 377 | |

| 80 | 165 | 130 | 195/200 | 160 | 135/132 | - | 20 | 8-18 | 410 | |

| 100 | 194 | 155 | 215/220 | 180 | 155/150 | - | 20/22 | 8-18 | 423 | |

| 125 | 210 | 185 | 245/250 | 210 | 185/184 | - | 22 | 8-18 | 436 | |

| 150 | 229 | 216 | 280/285 | 240 | 210/211 | - | 24 | 8-23 / 8-22 | 653 | |

| 200 | 243 | 264 | 335/340 | 295 | 265/266 | - | 26/24 | 12-23 / 12-22 | 703 | |

| 250 | 297 | 328 | 405 | 355 | 320/319 | - | 30/26 | 12-25 / 12-26 | 787 | |

| 300 | 338 | 373 | 460 | 410 | 375/370 | - | 30/28 | 12-25 / 12-26 | 827 | |

| 2.5 | 25 | 102 | 64 | 115 | 85 | 65 | - | 16 | 4-14 | 233 |

| 40 | 114 | 82 | 145/150 | 110 | 85/84 | - | 18 | 4-18 | 280 | |

| 50 | 124 | 100 | 160/165 | 125 | 100/99 | - | 20 | 4-18 | 362 | |

| 65 | 145 | 118 | 160/185 | 145 | 120/118 | - | 22 | 8-18 | 377 | |

| 80 | 165 | 130 | 195/200 | 160 | 135/132 | - | 22-24 | 8-18 | 410 | |

| 100 | 194 | 155 | 230/235 | 190 | 160/156 | - | 24 | 8-23 / 8-22 | 423 | |

| 125 | 210 | 185 | 270 | 220 | 188/184 | - | 28/26 | 8-25 / 8-26 | 436 | |

| 150 | 229 | 216 | 300 | 250 | 218/211 | - | 30/28 | 8-25 / 12-26 | 653 | |

| 200 | 243 | 264 | 360 | 310 | 278/274 | - | 34/30 | 12-25 / 12-26 | 703 | |

| 250 | 297 | 328 | 425 | 370 | 332/330 | - | 36/32 | 12-30 | 787 | |

| 300 | 338 | 373 | 485 | 430 | 390/389 | - | 40/34 | 16-30 | 827 | |

Hotline:

Hotline:

+86 13920768658

+86 13920768658