Nominal diameter: NPS2 "~ 32", DN50 ~ 1200mm

Nominal pressure: CL150, PN0.6 ~ 2.5MPa

Operating temperature: ≤200 ℃

Design criteria: API 600, API6D, ASME B16.34, GB / T 12234

Construction Length: ASME B16.10, API6D, GB / T 12221

Connection Standards: ASME B16.5, ASME B16.47, GB / T 9113, JB / T 79 , HG / T 20592

Pressure test: API 598, GB / T 13927, JB / T 9092

Pressure - Temperature class: ASME B16.34, GB / T 12224

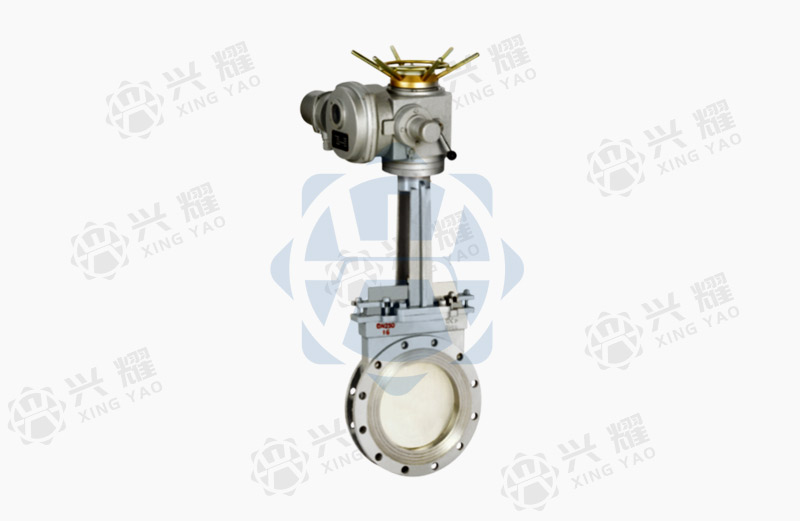

[Basic Information]

Electric knife gate valve

has the advantages of simple and compact structure, reasonable design,

light material, reliable sealing, light and flexible operation, small

volume, smooth passage, small flow resistance, light weight, easy

installation and easy disassembly. -2.5MPa, the use of temperature

-29-650 ℃ under normal circumstances. Knife gate valve with a shear

function, scraping off the sealing surface of the adhesive,

automatically remove debris, stainless steel gate to prevent corrosion

caused by leakage seal.

[Valve Features]

1, short structure length, save material, can greatly reduce the overall weight of the piping system.

2, take up less effective space, can effectively support the strength of the pipeline, reducing the possibility of pipeline vibration.

3, the gate selection of austenitic stainless steel, corrosion resistance greatly improved, which can effectively prevent the leakage caused by the gate seal leakage.

4, the sealing packing with flexible PTFE, reliable sealing, light and flexible operation.

5, the gate with a knife function, can effectively shut down all kinds of debris in the media.

6, such as the use of hard-sealed stainless steel, valve do spray welding, it can be a good extension of the valve on the temperature and pressure requirements.

[Adaptations]

Knife gate valve products are widely used in chemical, coal, food,

sewage, paper, steel and other fields, is an ideal seal valve.

The main shape and connection dimensions (mm):

| PN | DN | L | D1 | D2 | H | A | B | C | D | N-Φ | Denso models |

| 0.6MPa | 50 | 48 | 90 | 110 | 600 | 215 | 125 | 318 | 197 | 4-M12 | DZ10 |

| 65 | 48 | 110 | 130 | 670 | 215 | 125 | 318 | 197 | 4-M12 | DZ10 | |

| 80 | 51 | 125 | 150 | 680 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

| 100 | 51 | 145 | 170 | 700 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

| 125 | 57 | 175 | 200 | 720 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

| 150 | 57 | 200 | 225 | 790 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

| 200 | 70 | 255 | 280 | 850 | 215 | 125 | 363 | 197 | 8-M16 | DZ15 | |

| 250 | 70 | 310 | 335 | 1100 | 215 | 125 | 363 | 197 | 12-M16 | DZ20 | |

| 300 | 76 | 362 | 395 | 1180 | 215 | 125 | 363 | 197 | 12-M20 | DZ20 | |

| 350 | 76 | 412 | 445 | 1280 | 215 | 125 | 363 | 197 | 12-M20 | DZ30 | |

| 400 | 89 | 462 | 495 | 1460 | 215 | 125 | 363 | 197 | 16-M20 | DZ45 | |

| 450 | 89 | 518 | 550 | 1600 | 240 | 235 | 437 | 277 | 16-M20 | DZ45 | |

| 500 | 114 | 568 | 600 | 1800 | 240 | 235 | 437 | 277 | 16-M20 | DZ60 | |

| 600 | 114 | 670 | 705 | 2100 | 240 | 235 | 437 | 277 | 20-M22 | DZ60 | |

| 700 | 127 | 775 | 810 | 2300 | 274 | 260 | 526 | 283 | 24-M22 | DZ90 | |

| 800 | 127 | 880 | 920 | 2500 | 274 | 260 | 526 | 283 | 24-M27 | DZ120 | |

| 900 | 154 | 980 | 1020 | 2700 | 319 | 295 | 554 | 309 | 24-M27 | DZ180 | |

| 1000 | 165 | 1080 | 1120 | 2900 | 319 | 295 | 554 | 309 | 28-M27 | DZ250 | |

| 1200 | 190 | 1295 | 1340 | 2300 | 319 | 295 | 554 | 309 | 32-M27 | DZ250 | |

| 1.0MPa | 50 | 48 | 100 | 125 | 600 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 |

| 65 | 48 | 120 | 145 | 670 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

| 80 | 51 | 135 | 160 | 680 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

| 100 | 51 | 155 | 180 | 700 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

| 125 | 57 | 185 | 210 | 720 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

| 150 | 57 | 210 | 2400 | 790 | 215 | 125 | 363 | 197 | 8-M20 | DZ15 | |

| 200 | 70 | 265 | 295 | 850 | 215 | 125 | 363 | 197 | 8-M20 | DZ20 | |

| 250 | 70 | 320 | 350 | 1140 | 215 | 125 | 363 | 197 | 12-M20 | DZ20 | |

| 300 | 76 | 368 | 400 | 1180 | 215 | 125 | 363 | 197 | 12-M20 | DZ30 | |

| 350 | 76 | 428 | 460 | 1280 | 215 | 125 | 363 | 197 | 16-M20 | DZ30 | |

| 400 | 89 | 482 | 515 | 1460 | 240 | 235 | 437 | 277 | 16-M22 | DZ45 | |

| 450 | 89 | 532 | 565 | 1600 | 240 | 235 | 437 | 277 | 20-M22 | DZ45 | |

| 500 | 114 | 585 | 620 | 1800 | 240 | 235 | 437 | 277 | 20-M22 | DZ60 | |

| 600 | 114 | 685 | 725 | 2100 | 240 | 235 | 437 | 277 | 20-M27 | DZ60 | |

| 700 | 127 | 800 | 840 | 2300 | 274 | 260 | 526 | 238 | 24-M27 | DZ120 | |

| 800 | 127 | 898 | 950 | 2500 | 319 | 295 | 554 | 309 | 24-M30 | DZ180 | |

| 900 | 154 | 1005 | 1050 | 2700 | 319 | 295 | 554 | 309 | 28-M30 | DZ180 | |

| 1000 | 165 | 1115 | 1160 | 2900 | 319 | 295 | 554 | 309 | 28-M30 | DZ250 | |

| 1200 | 190 | 1325 | 1380 | 3400 | 319 | 295 | 554 | 309 | 32-M36 | DZ258 |

Hotline:

Hotline:

+86 13920768658

+86 13920768658